Routine Inspection

Efficient, non-invasive inspections designed for routine maintenance cycles and long-term reliability.

ROUTINE INSPECTION

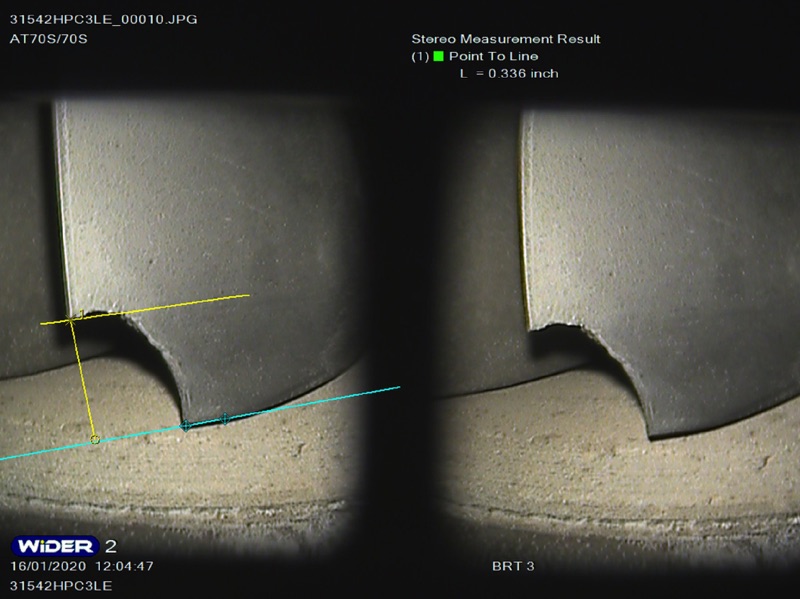

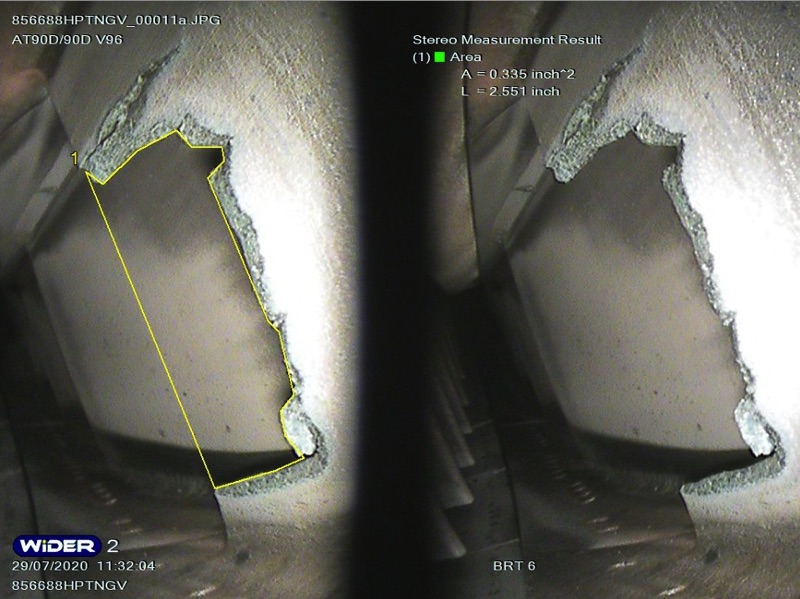

Routine borescope inspections are a regulatory and operational requirement in modern aviation maintenance.

Conducted at defined intervals, these inspections provide high-resolution internal imaging of critical engine components—without disassembly—ensuring ongoing airworthiness, performance tracking, and early fault detection.

Consistent Internal Condition Monitoring

Performed at flight-hour or cycle-based intervals, routine inspections capture standardised views of turbine blades, combustion liners, stators, and nozzles. This enables progressive wear tracking and comparison against manufacturer-defined limits.

OEM-Compliant Inspection Protocols

Inspections follow strict manufacturer guidelines (CFM, Pratt & Whitney, GE, Rolls-Royce, etc.), using defined port access, probe paths, and defect classification standards (e.g., dent, crack, FOD, erosion). This ensures data integrity and regulatory compliance.

Digital Archiving & Engine Trend Analysis

High-resolution stills and video footage are stored and cataloged for each engine serial number, supporting AD/SB compliance, lease return conditions, and long-term performance analytics across the fleet.

ROUTINE INSPECTION

Interval Scheduling & Inspection Scope