Full Inspection

Full-scope borescope solutions delivering detailed engine condition insights for confident decision-making.

Full INSPECTION

Full borescope inspections offer a complete internal assessment of all accessible engine sections.

Typically performed during scheduled heavy maintenance or lease transitions, these inspections provide a detailed condition profile of the engine’s gas path components, forming a critical part of lifecycle management and regulatory conformity.

Complete Gas Path Coverage

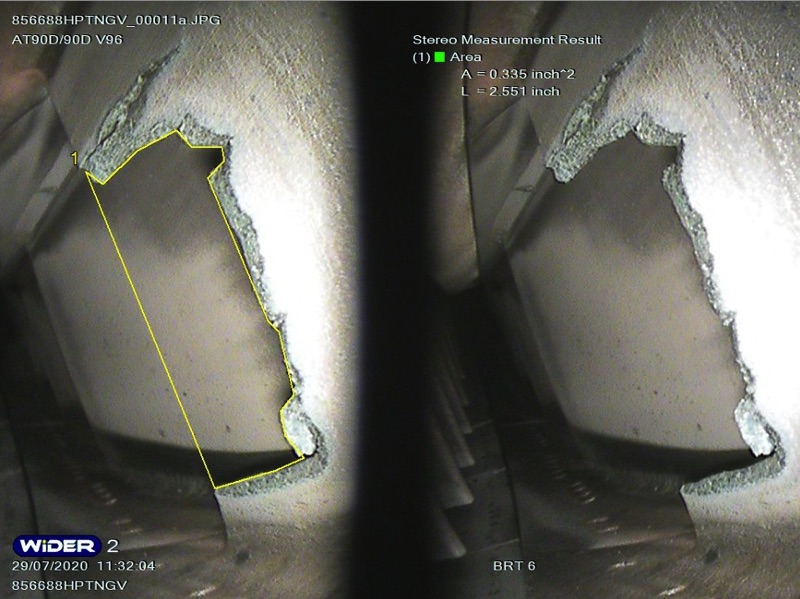

Inspections encompass the fan, compressor (LPC/HPC), combustion chamber, and turbine (HPT/LPT) stages. Technicians document the condition of blades, vanes, casings, seals, and liners to assess erosion, cracking, foreign object damage, or thermal distress.

Baseline Condition for Lifecycle Events

Full inspections establish an internal condition benchmark for major maintenance events, engine changes, lease transitions, or pre-purchase evaluations. This supports accurate valuation, planning for shop visits, and contract compliance.

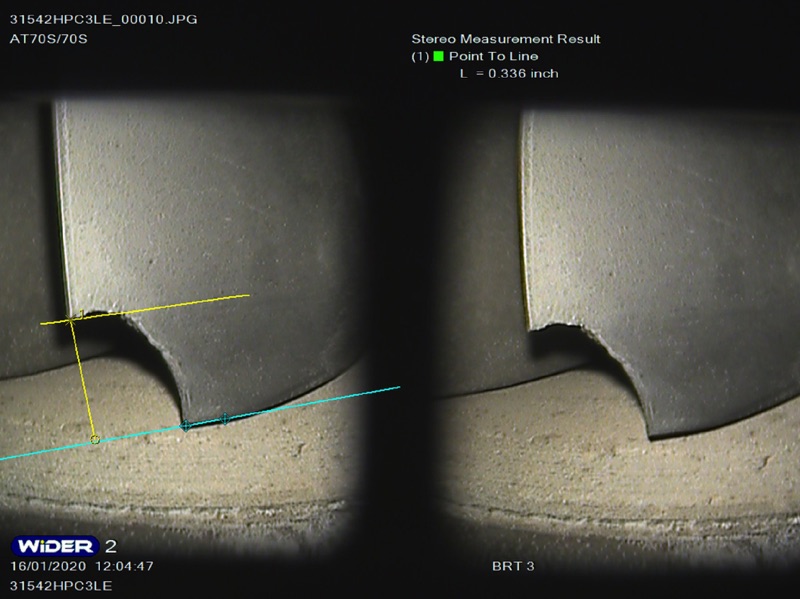

Quantitative Defect Assessment

Advanced video borescope systems capture high-resolution visuals and enable on-screen defect measurements. Findings are categorized using OEM damage criteria (e.g., dent depth, crack length) and supported by photo/video logs for technical records and audit trails.

FULL INSPECTION

Inspection Scope & Timing