Borescope Inspection of V2500 Compressors

RVI was asked to carry out a borescope inspection of the low pressure and high pressure compressors of a V2500 which had suffered an inflight surge in the descent phase of flight. The inspection was requested by the owners to try and determine the cause of the surge.

Damage Theories

There were a couple of theories as to the cause of the surge these being:

1. The ingestion of a foreign item such as a bird.

2. The internal failure of a component which then travelled into the gas path of the engine.

Engine History

The brief before I started the inspection explained that this engine surged while on lease to an operator. This operator had only used the aircraft with this engine installed for 2 flights.

They subsequently carried out a full borescope inspection and found severe damage in the high pressure compressor, so my inspection was not to determine serviceability but to try to determine the cause of the surge.

Engine History

A close inspection of the low pressure compressor revealed no damage and no signs of organic matter ingestion, I then looked round the void between the low and high pressure compressors to see if there were any signs of component failure or even signs of foreign objects that could have got into this area before installation. This engine had only done 2 flights since installation, 1st flight with no issues and the 2nd flight which suffered the surge.

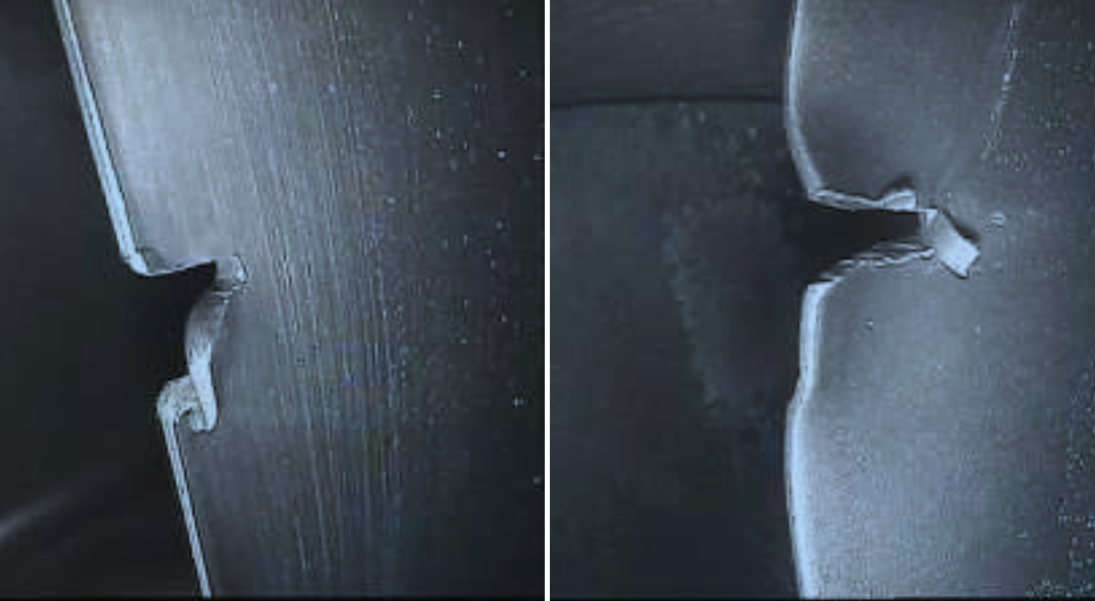

The inspection of the high pressure compressor showed several blades in the early stages with small but severe nicks which look new and were caused by a foreign object impacting the blades. These 2 images show the first and second stages with sharp cut like nicks.

Engine Inspection

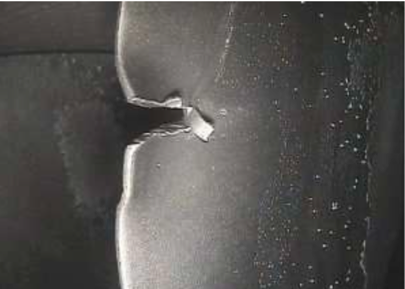

The area of most damage was stages 7 and 8 where I saw that a stator vane had sheared of at around 1⁄4 of the span of the vane. The liberation of this vane caused total devastation downstream.

The first and second images below show the remaining stub of the failed vane. There is a large section of leading edge missing which on closer inspection looks to be old damage, there are signs of dirt and the failure surface is discoloured unlike the surface where the vane failed is clean.

The following images give an idea of the downstream devastation caused by the failure of this vane.

Conclusion

This inspection virtually ruled out the possibility of ingestion of a foreign item and points towards an internal failure. We could not state whether the surge caused the vane to break or if the vane broke causing the surge.

The owners of the engine have accepted the operator did not do anything wrong or have an incident while operating the engine which would explain the surge. The engine will now have to be stripped down to further investigate the cause.